Search Products

Cavs Automotive Wires

10-500 INR/Piece

Product Details:

- Finish Smooth

- Material Copper conductor, PVC insulated

- Product Type Automotive Wire

- Corrosion Resistant Yes

- Weight Approx. 2.5 - 4 kg per 1000 meters (varies by size)

- Surface Treatment PVC insulation

- Temperature Range -20C to 70C

- Click to View more

X

Cavs Automotive Wires Price And Quantity

- 10-500 INR/Piece

- 1000 , , Piece

Cavs Automotive Wires Product Specifications

- 0.5 mm to 6 mm

- Silent

- Automobile electrical wiring

- CAVS-AW-001

- More than 5 years

- Extrusion and insulation

- Automotive Wire

- Copper conductor, PVC insulated

- Smooth

- Approx. 2.5 - 4 kg per 1000 meters (varies by size)

- Yes

- PVC insulation

- -20C to 70C

- Standard roll packaging, typically 90m/roll

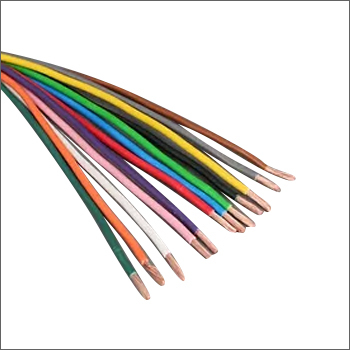

- Red, Blue, Yellow, Green, Black, White (various options available)

- Electrical Wire

- Up to 10 Amps (varies with specification)

- Cars, Trucks, Two-Wheelers

- Stranded or single core

Cavs Automotive Wires Trade Information

- 200 , , Piece Per Day

- 4-6 Days

Product Description

Being a foremost firm, we are providing an extensive range of CAVS Automotive Wires. These are basically used for automotive wiring and other industrial needs. Along with these, provided wires are made with a supreme quality of materials to withstand higher temperatures as well as stress than PVC. CAVS Automotive Wires ensure a low-tension circuits for automobiles purpose. They are a thin coating, which is easy to fix and use without facing any hassle.

Built for Automotive Standards

CAVS Automotive Wires are manufactured with strict compliance to IEC and IS:2465 standards, ensuring reliability and quality in automobile electrical systems. Each wire is crafted using advanced extrusion and insulation methods, resulting in high tensile strength and resistance against heat, chemicals, and UV rays. The use of pure electrolytic copper optimizes conductivity and boosts lifespan, making these wires dependable for both passenger and commercial vehicles.

Customizable and Versatile Solutions

Offered in standard coils or custom lengths, CAVS Automotive Wires provide versatility for automotive wiring requirements. Available in multiple colors and sizes (0.5 mm2 to 6 mm2), they are suitable for cars, trucks, and two-wheelers. Their flexibility simplifies routing during installation, while a choice between single core or stranded design ensures seamless integration with your specifications.

FAQ's of Cavs Automotive Wires:

Q: How are CAVS Automotive Wires installed in vehicles?

A: CAVS Automotive Wires can be installed using standard automotive wiring procedures, either as single core or stranded configurations. Their high flexibility allows for easy routing through tight spaces in various vehicle types, ensuring reliable connectivity to batteries, starters, lighting systems, and instrumentation circuits.Q: What are the key benefits of using pure electrolytic copper in these wires?

A: Pure electrolytic copper provides superior electrical conductivity, enhancing current flow and reducing voltage drops across circuits. This material also contributes to excellent tensile strength and corrosion resistance, making the wires long-lasting and efficient for automotive applications.Q: When should CAVS Automotive Wires be used in an automobile?

A: CAVS Automotive Wires are ideal for use during new installations, repairs, or upgrades of electrical wiring in vehicles. They are recommended whenever reliable, flame-retardant, and durable wiring is required for battery, starter, lighting, or instrumentation circuits.Q: Where can these automotive wires be used?

A: These wires are designed for versatile use in all types of automobiles, including cars, trucks, and two-wheelers. Their robust insulation and flexibility make them suitable for engine compartments, dashboards, and chassis wiring.Q: What is the process behind the manufacturing of CAVS Automotive Wires?

A: The wires are produced using an advanced extrusion process that ensures uniform insulation thickness and a smooth finish. Pure copper conductors are insulated with FR PVC, providing enhanced flame retardancy, chemical resistance, and UV protection. This method ensures consistent quality and compliance with international standards.Q: How does flame-retardant FR PVC insulation improve safety?

A: Flame-retardant FR PVC insulation minimizes the risk of fire by inhibiting flame propagation in the event of an electrical fault. This feature, combined with lead-free and RoHS compliant materials, provides enhanced safety for both the vehicle and its passengers.Q: What advantages do customized lengths and color options provide?

A: Customized lengths reduce waste and fit specific installation needs, while a range of color options allows for easy circuit identification, improving maintenance and reducing wiring errors during assembly or repairs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email