Search Products

Iso 6722 Class C Automotive Wires

300 INR/Piece

Product Details:

- Operating System Electrical Wiring Systems

- Product Type Automotive Wire

- Material Copper Conductor with Cross-Linked Polyethylene (XLPE) Insulation

- Part Type Wiring Harness Component

- Method Extrusion and Cross-Linking

- For Use In Automotive Electrical Systems

- Working Life Long-Term, exceeds standard automotive wire lifespan

- Click to View more

X

Iso 6722 Class C Automotive Wires Price And Quantity

- 300 INR/Piece

- 1000 , , Piece

Iso 6722 Class C Automotive Wires Product Specifications

- -40C to +150C

- Smooth Insulated Finish

- Standard Terminal/Crimp

- Passenger Cars, Commercial Vehicles, Two & Three Wheelers

- Yes

- Depends on selected cable size and reel

- Long-Term, exceeds standard automotive wire lifespan

- Standard to High Current (depends on size selection)

- Automotive Electrical Systems

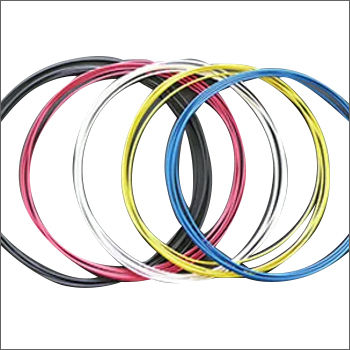

- Multiple (Red, Blue, Black, Yellow, etc.)

- Varies depending on size and length (refer datasheet)

- Insulated, Flame Retardant

- ISO 6722 Class C

- 0.5 mm to 6 mm (standard range)

- Automotive Wire

- Electrical Wiring Systems

- Extrusion and Cross-Linking

- Copper Conductor with Cross-Linked Polyethylene (XLPE) Insulation

- Wiring Harness Component

Iso 6722 Class C Automotive Wires Trade Information

- 200 , , Piece Per Day

- 4-6 Days

Product Description

We are affianced in dealing a superior range of ISO 6722 CLASS C Automotive Wires to our clients. These are highly durable and resistant to oil. These wires are suitable for trailer, construction, marine and others. Therefore, provided wires are used for general purpose electrical wiring of accessories. ISO 6722 CLASS C Automotive Wires are extremely flexible and reliable in nature. These wires are able to minimize the risk of shorts in electrical circuits.

Engineered for Demanding Environments

ISO 6722 Class C automotive wires are designed to handle the harsh conditions found in vehicle applications. Featuring cross-linked polyethylene (XLPE) insulation, these wires provide superior flexibility for complex routing, high abrasion resistance, and reliable performance under exposure to oils, fuels, coolants, and UV radiation. Their robust construction makes them suitable for both indoor and outdoor automotive wiring tasks.

Safety and Compliance You Can Trust

Safety is paramount in automotive electrical systems. These wires offer flame retardant properties and comply with automotive flammability standards, reducing fire risks. Their halogen-free composition supports environmental protection during operation and in case of fire. A dielectric strength greater than 25 kV/mm ensures excellent insulation and protection against electrical faults.

Versatile Use Across Vehicle Types

Available in conductor sizes from 0.5 mm2 to 6 mm2 and multiple color options, ISO 6722 Class C wires cater to a wide range of wiring requirements in passenger cars, commercial vehicles, and two or three wheelers. Their high load capacity and compatibility with standard terminals make them ideal as components in wiring harnesses across the automotive sector.

FAQ's of Iso 6722 Class C Automotive Wires:

Q: How do ISO 6722 Class C automotive wires ensure safety in vehicle electrical systems?

A: These wires feature flame-retardant, halogen-free XLPE insulation that meets automotive flammability standards, helping to minimize fire hazards. Their high dielectric strength further protects against electrical faults by preventing insulation breakdown.Q: What benefits do high flexibility and enhanced abrasion resistance provide?

A: High flexibility allows for easy installation and routing within tight or complex vehicle spaces, while enhanced abrasion resistance ensures the wires maintain integrity and performance even in rough or vibrating environments.Q: Where can ISO 6722 Class C wires be installed in vehicles?

A: These wires are suitable for both indoor and outdoor automotive applications, making them ideal for use throughout the vehicle's electrical system, including engine compartments, undercarriage, and passenger cabins.Q: What processes are used to manufacture these wires?

A: ISO 6722 Class C wires are produced using extrusion and cross-linking methods, which create durable cross-linked polyethylene (XLPE) insulation around the copper conductor, offering long-term reliability and excellent thermal properties.Q: When should I use these wires instead of standard automotive wires?

A: Choose ISO 6722 Class C wires for applications requiring higher temperature resistance (up to 150C), improved durability against chemicals, UV exposure, abrasion, and strict fire safety requirements. They are preferred for demanding or high-performance automotive wiring systems.Q: How do these wires perform under extreme environmental conditions?

A: With a temperature range from -40C to +150C, UV and chemical resistance, and corrosion protection, these wires maintain stable electrical performance and insulation integrity in challenging automotive environments.Q: What are the packaging and customization options for these wires?

A: Wires are available in rolls, coils, or customized packaging as per customer requirements, and offered in a range of standard sizes (0.5 mm2 to 6 mm2) and multiple insulation colors for easy identification and application in wiring harnesses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email