Search Products

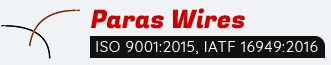

Paired PVC Cables

10-500 INR/Meter

Product Details:

- Armored Material Galvanized Steel Wire (optional)

- Features High durability, Flexibility, Flame retardant, High insulation resistance, Low attenuation

- Tensile Strength As per IS: 1554 standard

- Usage & Applications Suitable for secured signal transmission, process control, communication and electronics

- Insulation PVC Type A

- Core Material Copper

- Diameter Varies by core size & pairs; typically 3mm ~ 10mm

- Click to View more

X

Paired PVC Cables Price And Quantity

- 10-500 INR/Meter

- 1000 Meter

Paired PVC Cables Product Specifications

- Varies as per cable size and length

- 100 +/- 10 Ohms (typical)

- Grey

- Copper, PVC, (Steel armoring optional)

- Varies as per cable size

- Annealed Bare Copper

- Round

- PVC

- -15C to +70C

- Paired, Twisted Pair, Signal Cable

- 2 kV for 1 minute

- Indoor, Outdoor, Conduit, Trunking

- -20C to +75C

- -15C to +70C

- Industrial control panels, Communication systems, Instrumentation and signal transmission

- Paired PVC Insulated Cables

- 2 (paired), multi-pair on request

- 2 per pair, multiple pairs on request

- Copper

- Aluminum Mylar tape (Optional)

- Varies by core size & pairs; typically 3mm ~ 10mm

- 100 meters (standard); Custom lengths available

- PVC Type A

- Up to 1100V

- 0.5 mm, 0.75 mm, 1.0 mm, 1.5 mm, 2.5 mm (others on request)

- Stranded

- Not applicable / As per requirement

- High durability, Flexibility, Flame retardant, High insulation resistance, Low attenuation

- PVC (Polyvinyl Chloride)

- Galvanized Steel Wire (optional)

- Grey (jacket); Pair cores with color codes

- As per IS: 1554 standard

- Suitable for secured signal transmission, process control, communication and electronics

Paired PVC Cables Trade Information

- 200 Meter Per Day

- 4-6 Week

Product Description

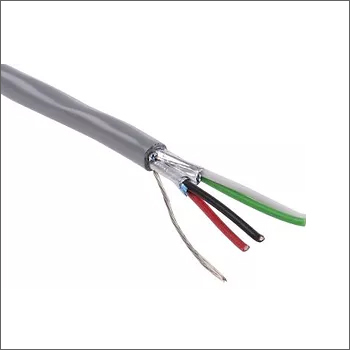

We are distributing a comprehensive assortment of Paired PVC Cables. These are easily available in all sizes and many applications such as offices, infrastructure, carrying signals etc. These cables are used to connect two or more devices to transfer electrical signals. Paired PVC Cables are tough and resistant to abrasion. They are used heavily in cable insulation due to its high mechanical strength. Provided cables are ideally suited for cables to be used in modern buildings.

Superior Twisted-Pair Construction

These cables feature twisted pairs that significantly reduce crosstalk and external electrical interference. This construction ensures signal integrity, making them especially suitable for sensitive communication and instrumentation applications. An optional aluminum mylar shield further boosts interference protection for demanding environments.

Flame Retardant and Safety-Compliant

Engineered with a flame-retardant PVC outer sheath (FR/FRLS), these cables boast an oxygen index above 29% and have low halogen content, meeting safety standards IS 7098 and IS 1554. Their robust construction provides reliable performance even in hazardous or densely wired installations.

Versatile Applications and Durability

Designed for both indoor and outdoor use, these cables withstand exposure to oil, chemicals, UV, and weather. They're highly flexible, easy to install in conduit or trunking, and come in various sizes and pair configurations to suit industrial control panels, communication systems, and signal transmission needs.

FAQ's of Paired PVC Cables:

Q: How do paired PVC cables minimize signal interference and crosstalk?

A: Paired PVC cables utilize twisted pair construction, which reduces electromagnetic interference and crosstalk between adjacent wires. The twisting causes external noise to affect the wires equally, allowing unwanted signals to be cancelled out, thereby ensuring better signal clarity.Q: What makes these cables flame retardant and safe for industrial installations?

A: The cables are manufactured with flame-retardant (FR/FRLS) PVC sheath as per IS 7098, having oxygen index values above 29%. They also have low halogen content and are tested to IS 1554 and IEC 189 standards, providing enhanced safety in case of fire and reducing the emission of toxic gases.Q: When should I choose shielded pairs versus unshielded pairs in these cables?

A: Optional shielded pairs, using aluminum mylar tape, are recommended in environments with high electromagnetic noise or where extra interference suppression is required, such as near heavy electrical equipment or in sensitive instrumentation applications. Unshielded pairs suffice in less noisy environments.Q: Where can these PVC paired cables be installed?

A: These cables are suitable for installation in indoor and outdoor locations, conduit, trunking, and control panels. Their robust, weather-resistant, and UV-resistant outer sheath ensures reliable performance in a variety of installation environments, including industrial sites.Q: What is the process for identifying cable cores and sheath marking?

A: Core identification is achieved through either number coding or color coding as per customer specifications. Additionally, the outer sheath features laser or ink markings at regular intervals, ensuring easy identification of cable type and specifications during installation and maintenance.Q: How do these cables benefit industrial control and communication systems?

A: With features such as low attenuation, high insulation resistance, and excellent noise reduction thanks to twisted pair construction, these cables provide secure and consistent signal transmission essential for process control, communication, and instrumentation tasks.Q: What lengths and sizes are available, and are custom configurations possible?

A: Standard cable lengths are 100 meters, but custom lengths and multi-pair configurations are available upon request. Sizes range from 0.5 mm2 to 2.5 mm2 (others upon request), offering flexibility to meet specific project or system requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email