Search Products

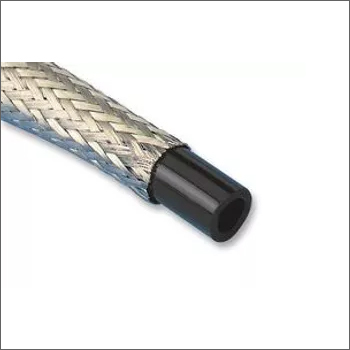

Light Weight Copper Braids

10-500 INR/Meter

Product Details:

- Diameter From 1 mm up to 50 mm

- Condition New

- Surface Treatment Tinned or Bare Copper

- Cross Dimension Up to 120 sq mm

- Finish Smooth

- Outer Diameter Depends on braid type

- Size Available in Various Sizes

- Click to View more

X

Light Weight Copper Braids Price And Quantity

- 1000 Meter

- 10-500 INR/Meter

Light Weight Copper Braids Product Specifications

- Tinned or Bare Copper

- High Flexibility & Conductivity

- New

- 4 mm - 50 mm

- Copper Red or Silver (Tinned)

- From 1 mm up to 50 mm

- 0.2 mm - 1.5 mm

- E-Cu (Electrolytic Copper)

- Smooth

- Flat or Round

- Up to 120 sq mm

- Depends on braid type

- Light Weight Copper Braids

- Soft Annealed

- Available in Various Sizes

- ASTM B3 / IS 191

- Custom or Standard Lengths Available

Light Weight Copper Braids Trade Information

- 200 Meter Per Day

- 4-6 Week

Product Description

We are offering here the Light Weight Copper Braids that finds use in many different forms and components due to its strength, flexibility and superior ability to handle large currents at low voltages. This makes copper braided wire a perfect choice as a flexible grounding strap when rolled flat. It is used for power and mass connections, and, when suitably insulated, as an alternative to the cables. The offered Light Weight Copper Braids are very useful.

Unmatched Performance and Reliability

Experience superior conductivity and durability with our fine copper braided products. Designed for flexibility and efficient current transfer, these braids are essential in demanding electrical, automotive, and industrial environments. Each braid is engineered to withstand temperatures from -20C to +80C, ensuring reliable operation across diverse conditions. Their fire-resistant properties make them a safe choice for critical electrical connections.

Customizable Solutions for Varied Applications

Our copper braids can be tailored to your specific requirements, including length, width, thickness, and surface finish. Whether you need flat or round shapes, tinned or bare copper surface, we provide options to match your unique project needs. Packed in rolls or coils and available in cross dimensions up to 120 sq mm, they resolve a variety of connectivity challenges with ease.

FAQ's of Light Weight Copper Braids:

Q: How are the light weight copper braids manufactured for optimal conductivity?

A: These copper braids are made with fine E-Cu (Electrolytic Copper) wires, using a specialized annealing process to achieve a soft, flexible structure with smooth finish. This ensures low resistivity and efficient current transfer, meeting IEC/BS/DIN standards.Q: What are the primary benefits of using these copper braids in electrical and automotive applications?

A: The primary benefits include excellent flexibility, high conductivity, fire resistance, and low resistivity. These features enable safe, efficient earthing and reliable performance in electrical panels, automotive assemblies, and flexible interconnections.Q: When should tinned copper braids be selected over bare copper braids?

A: Tinned copper braids are ideal for environments prone to corrosion or exposure to moisture, as the tin coating provides extra protection. Bare copper braids are suitable where high conductivity and cost-effectiveness are priorities.Q: Where can these copper braids be used apart from electrical panels and automotive industries?

A: Besides electrical and automotive sectors, these braids are commonly used in industrial equipment, machinery earthing, telecommunications, and any application that requires flexible, high-conductivity power or signal connections.Q: What is the process for customizing copper braids to fit unique project requirements?

A: Customization involves specifying your desired dimensions (length, width, thickness, cross-section), surface treatment (tinned or bare), and packaging type (rolls or coils). The manufacturer then engineers the braid accordingly, ensuring it meets your application needs and quality standards.Q: How does the copper braid's fire resistance benefit its usage in sensitive installations?

A: The fire-resistant nature of these copper braids enhances safety in sensitive electrical and industrial environments by minimizing risks associated with overheating or electrical faults, thus protecting equipment and personnel.Q: What standards and compliance certifications do these copper braids adhere to?

A: They are manufactured in compliance with international standards including IEC, BS, and DIN, and are RoHS certified, ensuring both safety and environmentally responsible production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email