Search Products

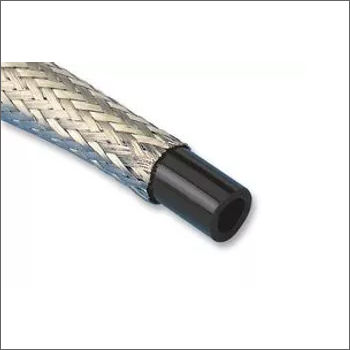

Plated Copper Braids

10-500 INR/Meter

Product Details:

- Outer Diameter Depends on braid strand and configuration

- Finish Electro-Plated

- Condition New

- Size Custom sizes available

- Diameter Custom (for round braids)

- Surface Treatment Tinned Plated / Silver Plated

- Cross Dimension Depends on braid width and thickness

- Click to View more

X

Plated Copper Braids Price And Quantity

- 10-500 INR/Meter

- 1000 , Meter

Plated Copper Braids Product Specifications

- Soft/Annealed

- Copper

- Braided Copper Strips / Braided Copper Wire

- Custom as per requirement

- Depends on braid width and thickness

- Tinned Plated / Silver Plated

- Flat / Hollow / Round

- Varies (Typically 0.5 mm to 3 mm)

- Custom (for round braids)

- Bright copper / Silver (depending on plating)

- Varies (Typically 5 mm to 50 mm)

- Custom sizes available

- High tensile strength

- New

- EC Grade / Pure Copper

- Depends on braid strand and configuration

- Electro-Plated

Plated Copper Braids Trade Information

- 200 , Meter Per Day

- 4-6 Week

Product Description

We are able to supply a wide stock of Plated Copper Braids. These are used in telecommunication cable, grounding wires and much more. These braids are available in different dimensions that are as per the specification of the customer. They are easy to handle and use. Plated Copper Braids are highly demanded in the electrical industry. These braids are also useful to protect coverings due to its tinned copper coating. These are made of most other conductive metals because they are resistant to heat.

Superior Electrical Performance and Purity

Our plated copper braids are engineered from 99.9% pure copper, guaranteeing outstanding electrical conductivity and minimal resistance. The tin or silver electroplating not only enhances conductivity but also significantly increases corrosion resistance, making these braids suitable for long-term use in harsh environments. They conform to the highest material purity standards, ensuring reliable and efficient transmission of current in critical applications.

Flexible Options for Versatile Applications

Offered in flat, hollow, or round shapes, and in a range of customizable sizes, our copper braids cater to diverse industry requirements, from earthing and grounding to use in flexible joints and busbar connections. Their soft, annealed construction and multi-stranded design provide excellent pliability, making installation straightforward even in confined spaces. Custom lengths and dimensions can be requested to meet unique project specifications.

Corrosion Resistance and Durable Construction

Electroplated with tin or silver, these copper braids combine outstanding flexibility with enhanced resistance to oxidation and environmental degradation. The high tensile strength of the EC grade copper wires ensures durability under repeated flexing and mechanical stress, while the absence of insulation allows for superior heat dissipation and easy integration into any electrical setup.

FAQ's of Plated Copper Braids:

Q: How are plated copper braids typically used in electrical systems?

A: Plated copper braids are most commonly used for grounding (earthing), flexible electrical connections between busbars, and as jumpers in equipment where superior conductivity and flexibility are required. Their high corrosion resistance makes them suited for both indoor and outdoor applications.Q: What benefits do tin or silver electroplated finishes provide compared to bare copper?

A: Tin or silver plating enhances the braid's resistance to corrosion, particularly in humid or chemically aggressive environments, while maintaining or improving electrical conductivity. This results in longer service life and reliable performance even under challenging operating conditions.Q: Can I order plated copper braids in custom sizes and configurations?

A: Yes, customization is available as per your drawing or sample. You can specify the desired width, thickness, length, braid shape (flat, round, or hollow), and plating type (tin or silver) to suit your specific application requirements.Q: Where are these plated copper braids manufactured and supplied from?

A: These braids are marketed by leading Indian manufacturers, exporters, and suppliers. They can be delivered from ready stock or produced specifically to order, depending on your needs and the supplier's policy.Q: What is the typical process for manufacturing plated copper braids?

A: Multi-stranded fine copper wires are braided into the desired configuration, then thoroughly cleaned and electroplated with tin or silver. This process ensures a uniform, conductive finish that offers both excellent electrical properties and superior corrosion resistance.Q: How flexible and durable are these braids during installation and use?

A: The braids are highly flexible, making them easy to shape and install in tight spaces. Despite this flexibility, they maintain high tensile strength and durability, resisting mechanical fatigue over extended periods of use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email