Search Products

Flry Type A And B Automotive Wires

300 INR/Piece

Product Details:

- Dimension (L*W*H) Customized as per requirement

- Finish Smooth PVC finish

- Method Extruded and insulated

- Load Capacity Depends on gauge; up to 60V

- Temperature Range -40C to +105C (A); -40C to +125C (B)

- Vehicle Type Passenger cars, commercial vehicles, two-wheelers

- Model No FLRY A, FLRY B

- Click to View more

X

Flry Type A And B Automotive Wires Price And Quantity

- 300 INR/Piece

- 1000 Piece

Flry Type A And B Automotive Wires Product Specifications

- Crimped, soldered or connector based

- Varies as per length and gauge

- PVC coated

- 0.5 sqmm to 6.0 sqmm

- Electrical automotive circuits

- Automobile electrical systems

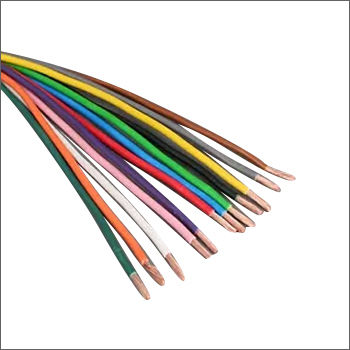

- Multiple colors available

- Long service life under recommended conditions

- Copper conductor with PVC insulation

- Yes

- Wiring/Automotive cable

- Automotive Wire

- Passenger cars, commercial vehicles, two-wheelers

- FLRY A, FLRY B

- -40C to +105C (A); -40C to +125C (B)

- Depends on gauge; up to 60V

- Extruded and insulated

- Customized as per requirement

- Smooth PVC finish

Flry Type A And B Automotive Wires Trade Information

- 200 Piece Per Day

- 4-6 Days

Product Description

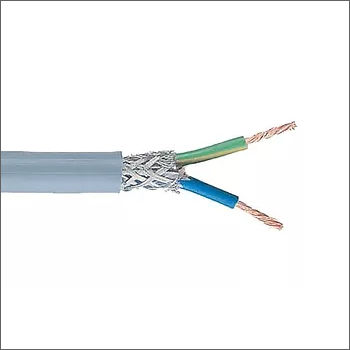

Our firm is instrumental in providing a wide stock of FLRY Type A And B Automotive Wires. These are designed for automotive applications. These wires are made of several strands and innovative techniques. They are formed in a thin coating material to give a great performance. FLRY Type A And B Automotive Wires are also useful in motor vehicles for starting and instrument panel circuits. These wires are able to reduce the higher current carrying capacity.

Engineered to Withstand Automotive Demands

FLRY Type A and B wires meet rigorous international standards like ISO 6722 and SAE J1128, offering reliable performance in the harsh environments of automobile electrical circuits. Their flame-retardant and UV-resistant properties provide added safety while PVC insulation ensures both flexibility and a long service life, even when routed through tight vehicle spaces.

Versatile Applications and Configuration Options

Available in sizes from 0.5 sqmm to 6.0 sqmm, and in multiple colors, FLRY wires can be tailored to meet specific vehicle requirements. These wires support a voltage rating of up to 60V and can be installed using crimped, soldered, or connector-based methods, ensuring compatibility with various automotive harness and wiring loom applications.

Superior Material Selection for Lasting Performance

Manufactured with premium multistrand copper and extruded PVC insulation, FLRY wires exhibit excellent corrosion resistance and a smooth finish. The wires are available in coils or spools, and the manufacturing process ensures consistent quality, making them ideal for exporters, manufacturers, and suppliers across India and globally.

FAQ's of Flry Type A And B Automotive Wires:

Q: How are FLRY Type A and B automotive wires used in vehicles?

A: FLRY Type A and B wires are commonly used in automotive wiring harnesses and looms, providing reliable connections for electrical systems in passenger cars, commercial vehicles, and two-wheelers. Their high flexibility allows them to be routed efficiently through tight spaces in modern vehicles.Q: What is the benefit of using FLRY automotive wires with flame retardancy?

A: The flame-retardant properties, as per ISO 6722, significantly enhance safety by reducing fire risk in the event of electrical faults, ensuring greater protection for vehicle occupants and components.Q: When should I choose FLRY Type A over Type B automotive wires?

A: Choose FLRY Type A for operating temperatures up to +105C, while FLRY Type B is suitable for environments requiring higher temperature tolerance up to +125C. Selection depends on specific thermal requirements of your application.Q: Where can these automotive wires be installed?

A: FLRY wires are designed for installation within the electrical circuits and wiring looms of all types of vehicles, including passenger cars, commercial vehicles, and two-wheelers. They are suitable for interior as well as protected exterior areas due to their robust insulation and UV resistance.Q: What process is used to manufacture FLRY Type A and B wires?

A: These wires are manufactured using an extrusion process to insulate multistrand copper conductors with high-quality PVC, resulting in a smooth and consistent finish with precise insulation thickness.Q: How do I select the appropriate size and color for my automotive wiring needs?

A: You can choose from sizes ranging between 0.5 sqmm to 6.0 sqmm, and multiple colors, according to the electrical load and identification requirements of your vehicle's wiring configuration. Custom dimensions are also available to meet specific project needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email